ElectroCicla

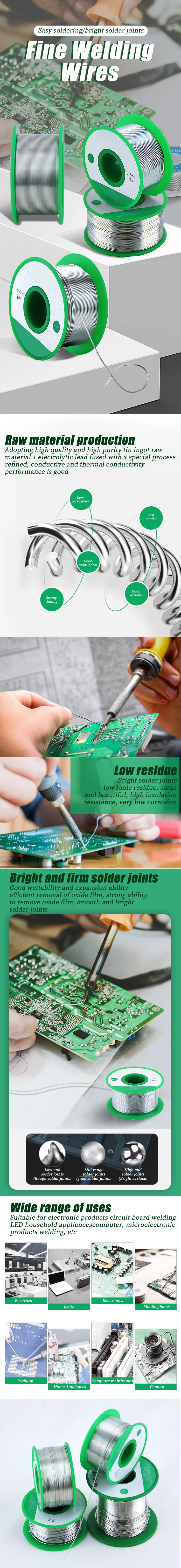

Rollo Alambre Soldadura Sin Plomo (Sn99.3/Cu0.7) Alta Pureza para Reparación Electrónica (Flux Protección Ambiental)

Rollo Alambre Soldadura Sin Plomo (Sn99.3/Cu0.7) Alta Pureza para Reparación Electrónica (Flux Protección Ambiental)

No se pudo cargar la disponibilidad de retiro

SPECIFICATIONS

Brand Name: NLZD

Certification: RoHS

Choice: yes

Hign-concerned Chemical: None

Material: tin

Origin: Mainland China

Type 1: tin solder wire

Type 2: soldering wire

Type 3: Solder tin

Type 4: lead free solder wire

Type 5: Sn99.3/Cu0.7

Type 6: Soldering Wire Roll

Type 7: tin Wire Flux

Weight: 30

semi_Choice: yes

Describe

【 High quality lead-free solder wire 】Our wires are made of high quality, environmentally friendly lead-free solder, RoHS compliant and suitable for a wide range of welding tasks.

【 Rosin core flux 】The rosin cored flux is built into the wire to ensure excellent welding performance. The rosin core flux is evenly distributed, so that the solder joint is firm and smooth, and the welding quality is improved.

【 Wire performance 】Low melting point, good activity, high insulation resistance, fast welding speed, reduce the thermal shock caused by welding components. Reduce welding time and improve production efficiency. Suitable for fine welding operations and various electronic parts maintenance.

【 Widely used 】Lead-free solder wire is widely used, suitable for electronic repair, circuit board manufacturing, lead-free welding, model making, DIY projects, etc.

【 Smooth flow 】Our solder wire ensures good flow and enables a smooth welding process, improving welding accuracy and efficiency.

Usage

1、When used, in order to obtain a good welding effect, the welded part must be weldable, the surface of the welded metal should be kept clean, the use of appropriate lead-free soldering iron head.

2、After opening the soldering iron switch, wait until the soldering iron temperature rises to the required operating temperature before welding.

3、The operator's head should be 20 CM away from the pad.

4、When the soldering iron is not in use, a layer of tin should be plated on the soldering iron, and then turn off the power switch.

5、The working area should be equipped with a suitable air flotation device.

Compartir